- 知从木牛SafetyLibrary旗芯微FC7300

- 知从木牛SafetyLibrary旗芯微FC7240

- 知从木牛SafetyFrame赛普拉斯CYT2B7

- 知从木牛SafetyFrame瑞萨RH850/U2AX

- 知从木牛SafetyFrame瑞萨RH850F1KM

- 知从木牛BCC恩智浦MC33771

- 知从木牛SafetyLibrary恩智浦MPC5744P

- 知从木牛SafetyLibrary英飞凌TC377

- 知从木牛Safetylibrary意法半导体SPC58NH

- 英飞凌TC3XX_MTU模块介绍以及使用方法

- 知从木牛SafetyFrame瑞萨RH850/P1M-C

- 知从木牛SAFETYFRAME瑞萨RH850/U2CX

- 知从木牛SAFETYLIBRARY旗芯微FC7300F8MDQ

- 知从-云途YTM32B1H/M功能安全库SAFLIB产品

- 知从木牛-恩智浦FS26功能安全

- 知从木牛SafetyLibrary意法半导体SPC58NN

- 知从木牛复杂驱动CDD恩智浦MC33774

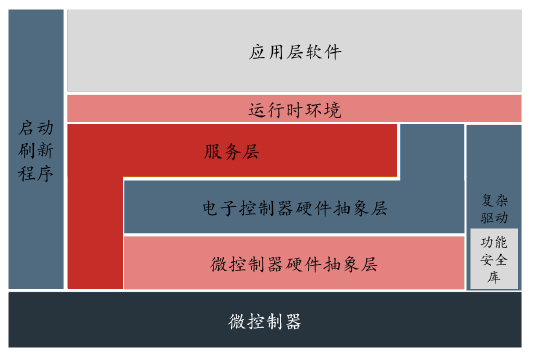

- 知从木牛SafetyFrame

- 知从木牛SafetyLibrary恩智浦MPC5746C

- 知从木牛SafetyLibrary恩智浦MPC5748G

- 知从木牛SafetyLibrary软件平台恩智浦S32K14X

- 知从木牛SafetyLibrary英飞凌TC2XX

- 知从木牛SafetyLibrary英飞凌TC275

- 知从木牛SafetyLibrary英飞凌TC397

- 知从木牛SBC恩智浦FS6500-FS4500

- 知从木牛SBC英飞凌TLF35584

目前,汽车上的电子电气架构越来越复杂,对汽车电子的安全性要求也越来越高,为了满足汽车的安全性需求,汽车功能安全越来越受到重视。提到功能安全,大家首先想到的是功能安全的标准ISO26262。其中,ISO 26262-5(2018) Clause 8中介绍了2个度量:Single-point fault metric(单点故障度量)和Latent-fault metric(潜伏故障度量)。根据不同的ASIL等级要求,单点故障度量和潜伏故障度量需要达到相应的等级。

对于微控制器(MCU,以下简称MCU),在电子电气系统中,作为SEooC(safety element out of context)进行设计开发。MCU为了满足以上提到的2个度量要求,需要实现相应的安全机制。而安全机制可以分配到硬件和软件模块中。MCU的Safety Frame安全库就是实现分配到软件上的安全机制。

1.产品特点

Ø可作为复杂驱动集成到AUTOSAR中

Ø可集成到非AUTOSAR软件架构中,灵活适配

Ø支持多核测试及应用

ØSafety Frame具有内部程序流监控

Ø高安全性:支持自检测试,搭配知从科技SBC复杂驱动可实现高达ASIL-B需求

Ø高扩展性:各模块可配置满足不同客户的应用需求

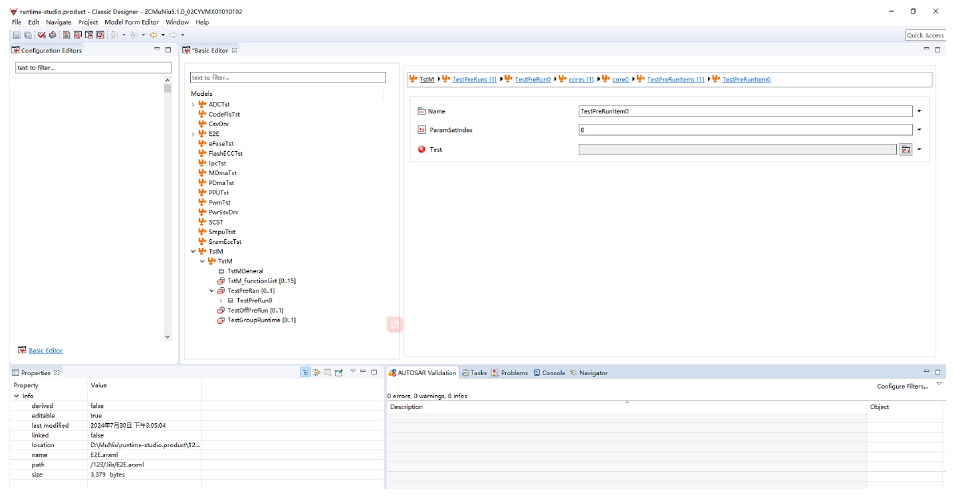

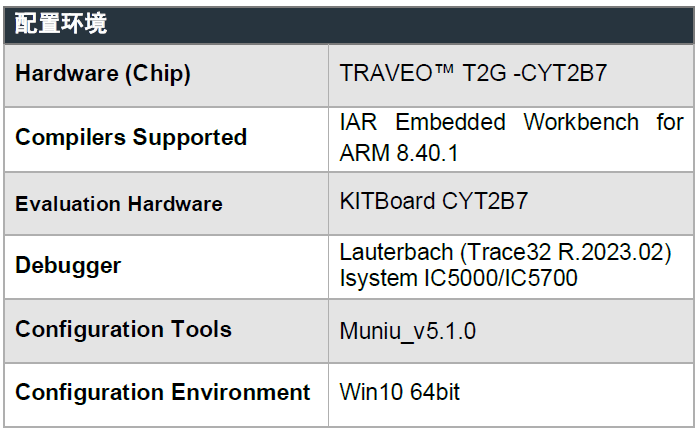

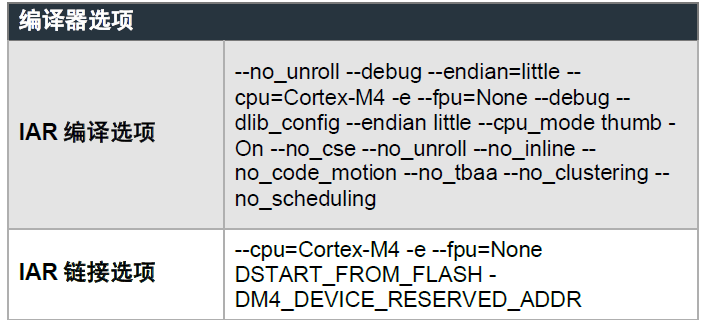

2.配置工具

为了满足客户的不同项目需求,提高Safety Frame的扩展性,CYT2B7 Safety Frame实现了各个模块可配置性,并且实现了Safety Frame的配置工具。客户可根据不同需求,在配置工具上完成Safety Frame各个模块的配置工作,可生成配置代码文件,将生成的配置文件集成到工程中即可。

3.运行阶段

Ø预运行阶段

此阶段是对MCU的安全机制进行测试,一般此阶段在OS启动之前进行。

Ø运行阶段

此阶段是在任务运行时进行,在OS运行时进行,同时部分MCU的安全机制在此阶段进行测试。

4.过程文档

CYT2B7 Safety Frame用于帮助客户实现基于CYT2B7平台的功能安全要求。Safety Frame具有高扩展性,可以根据不同的客户项目要求进行配置和再开发,最终满足客户的功能安全需求。

CYT2B7 Safety Frame用于实现TRAVEO™ T2G系列的软件安全机制 ,包括MCU内部模块的测试和硬件安全机制的驱动。

CYT2B7 Safety Frame可应用于有功能安全等级需求的控制器。

例如:

Ø汽车车身电子设备

Ø汽车车身控制模块 (BCM)

Ø带集成网关的车身控制模块 (BCM)

Ø汽车网关

Ø汽车LED前照灯

通过将Safety Frame集成到基于CYT2B7 的控制中,可达到ISO26262 ASIL-B的等级要求。

实现的功能模块:

满足CYT2B7 Safety Manual中的MXS:

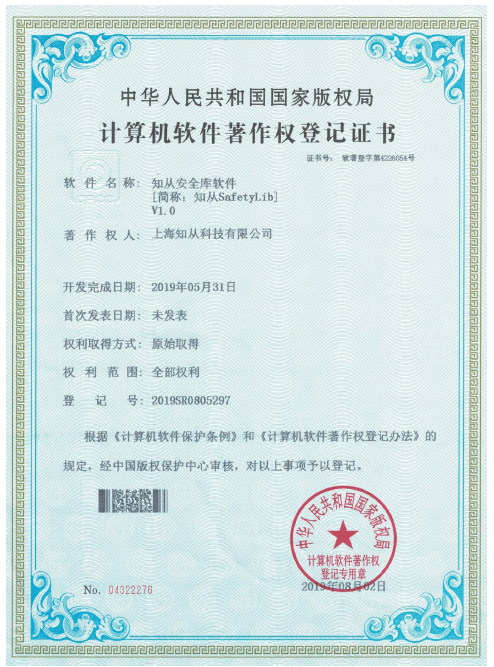

功能安全证书

证书

点击下载产品手册