1 黑匣子产品功能

1.1 产品特点

黑匣子用于记录汽车运行时的运行状态。在过去的汽车事故中,往往会由于车辆损毁严重,导致无法获取事故发生时的车辆状态,使得无法保证驾驶员的权益,并且不能确定车辆是否存在问题。因此,通过黑匣子中存储的数据可以有效解决上述问题。

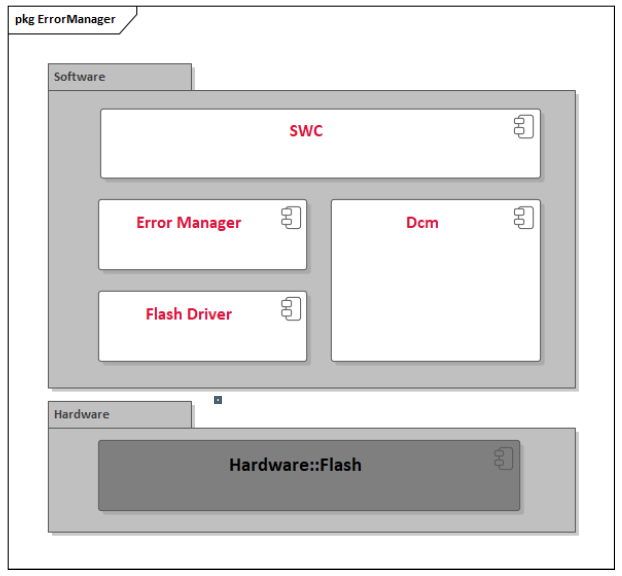

图 4- 1 架构原理图

1.2 实现方案

TC277支持的DFlash空间大小为384KB。由于DFlash区域有数据掉电不丢失的特点,因此用于存储故障数据。

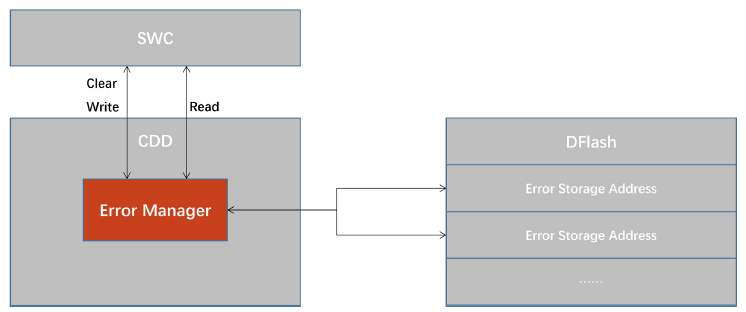

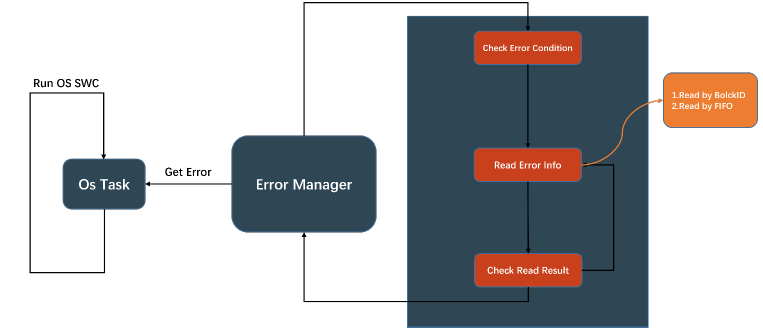

在CDD层增加用于故障管理的Error Manager模块功能。上层SWC层出现故障时,可以调用Error Manager模块来传递故障相关信息,而后Error Manager模块将获取到的数据写入DFlash中储存。如下图4-2所示。

SWC层也可以调用Error Manager的清除功能来清除DFlash中存储的数据,去除掉已经无用的数据,保证有足够的空间存储后续新的故障信息。

通过Error Manager模块的读取接口可以获取到DFlash中已经存储的数据,并将故障信息上报至上位机工具,方便测试人员获得故障信息以用于排查车辆存在的故障。

图 4- 2 故障存储框架

1.3 故障存储流程

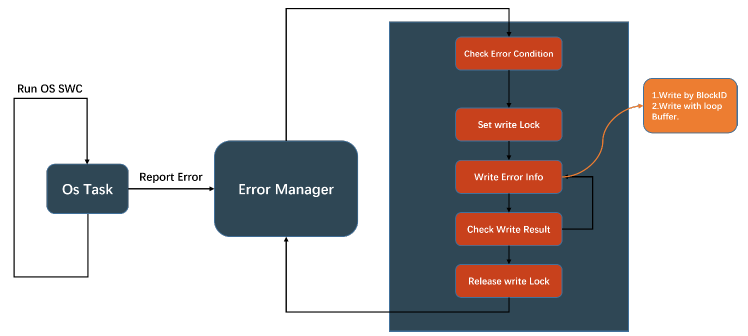

图 4- 3 故障存储流程

在应用层周期任务中上报故障后,故障管理模块(Error Manager)会依次进行以下流程:

1. 检查需要记录的故障是否满足条件。

2. 锁定当前要记录数据的DFlash区域,防止其他任务再次调用写入功能。

3. 将故障信息写入DFlash区域。

4. 检查写入的结果是否正确。

5. Error Manager模块写入完成。

1.4 故障清除流程

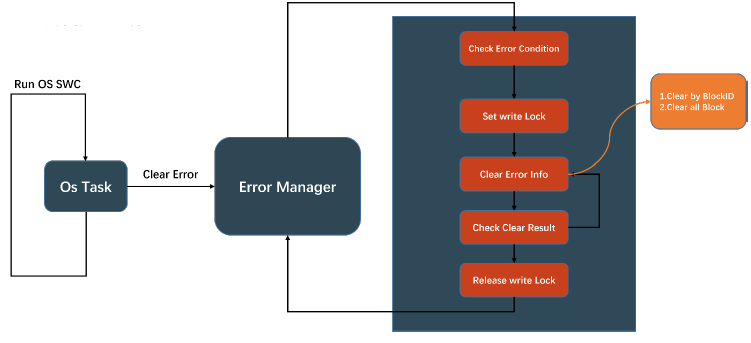

图 4- 4 故障清除流程

在应用层周期任务中下达清除故障的要求后,故障管理模块(Error Manager)会依次进行以下流程:

1. 检查需要清除的故障是否满足条件。

2. 锁定当前要操作的DFlash区域,防止其他任务调用清除功能。

3. 将存储的数据清除。

4. 检查清除结果是否正确。

5. Error Manager模块清除数据完成。

1.5 故障读取流程

图 4- 5 故障读取流程

在应用层周期任务中需要获取故障信息后,故障管理模块(Error Manager)会依次进行以下流程:

1. Error Manager模块检测故障状态。

2. 读取存储在DFlash中的数据。

3. 读取完成后,检测读取状态,并上报读取的数据。

2 知从玄武产品功能

2.1 产品特点

为了配合黑匣子的数据回放,知从科技推出的玄武诊断测试工具可以对黑匣子内存储的数据进行读取,使得技术人员可以更轻松地获取故障数据。

知从玄武有如下特点:

Ø 操作简易

n 图形化界面,方便配置

n 自动解析黑匣子数据如DID, DTC并生成excel

n 支持不同OEM的诊断配置和诊断规范

Ø 使用灵活

n 支持CAN、CAN FD、Kline协议

n 支持ISO 14229、ISO 15765、ISO 14230等标准

n 支持多种硬件接口

Ø 支持定制服务

2.2 回放功能

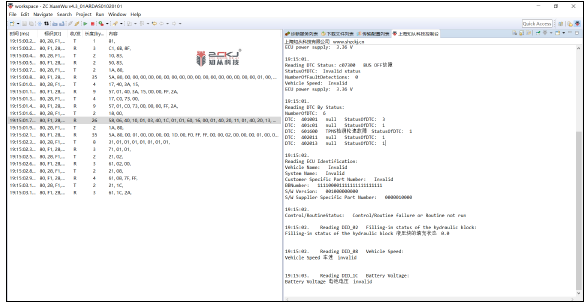

玄武上位机能够通过诊断服务获取黑匣子存储空间的故障信息、完成故障信息的解析,并将解析的故障数据信号以图形界面的形式展示。

图 5- 1 数据回放

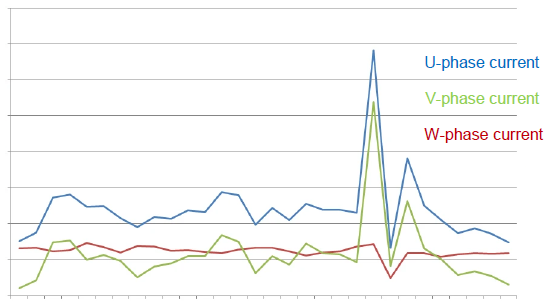

玄武上位机能够将解析的故障发生时的数据如U相电流、V相电流、W相电流随时间的变化绘制成波形图。

图 5- 2 数据回放图形界面

2.3 测试用例

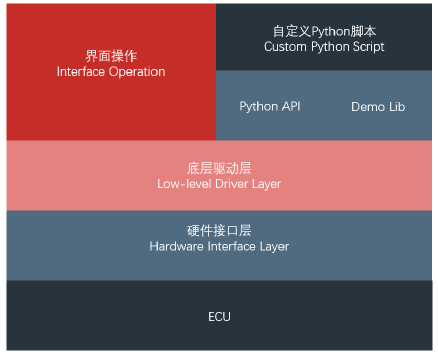

玄武支持基于Python的测试用例开发,同时提供了诊断服务的Python API接口,方便用户二次开发。

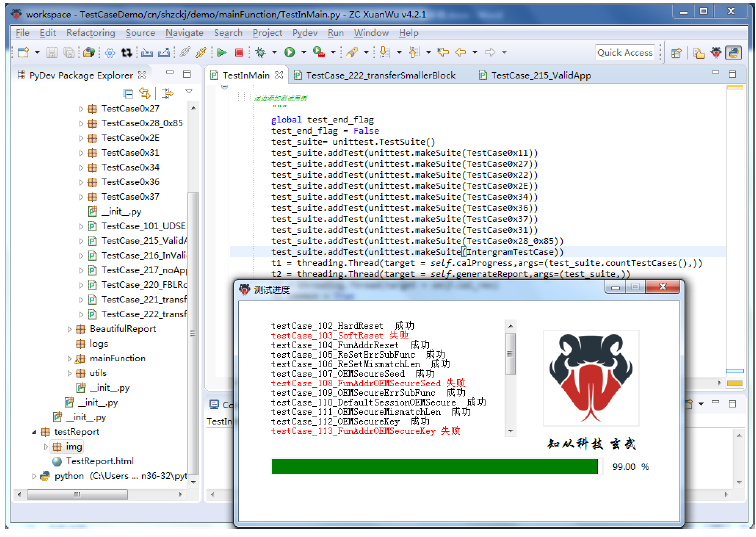

图 5- 3 Python API示意

根据黑匣子回放功能的需求,测试工程师编写了一套完整的测试用例,包括数据的存储、擦除、反复读写、压力测试等,通过玄武工具可实现自动化的测试。

图 5- 4 自定义测试程序

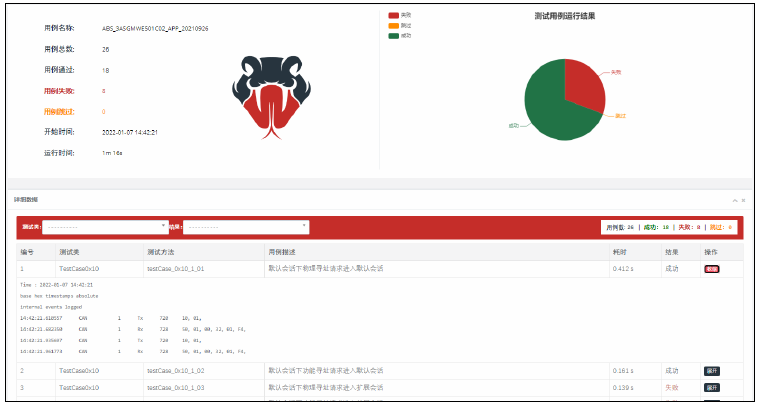

2.4 测试报告

针对测试结果,玄武工具可以自动生成测试报告。

图 5- 5 测试报告

汽车黑匣子,即汽车事件数据记录系统(Event Data Record,缩写为 EDR)。作为汽车控制器的重要功能之一,这套系统主要负责记录车辆发生事故时的行车数据,包括发生碰撞前、碰撞时、碰撞后三个阶段的汽车运行数据,例如速度、ABS状态、方向盘转向角度、气囊状态、车辆制动状态等。

黑匣子具有防篡改和可读写特性,与飞机上的黑匣子的功能相似。黑匣子通过CAN对车辆运行数据进行连续监控,当车辆在一定时间内的速度变化量达到预先设定的阈值(发生事故)时,黑匣子便将碰撞前至碰撞后共计几秒钟内的车辆情况信息储存起来,技术人员可以通过黑匣子中存储的这些数据来分析车辆存在的故障或者找到事故发生的原因。

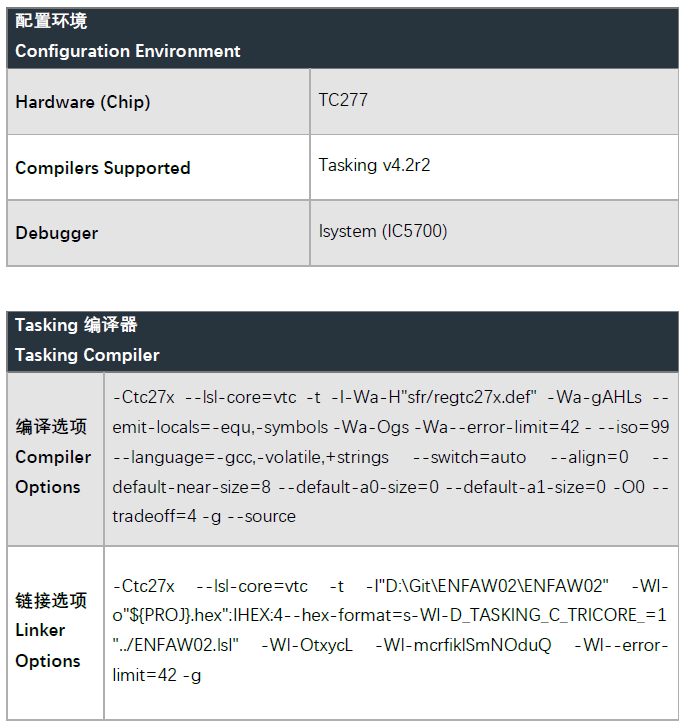

此文档描述了基于英飞凌TC277平台设计的黑匣子。目前支持多家整车厂的黑匣子规范。支持多数据存储,支持数据写入、读取及清除,支持上位机基于UDS诊断服务的读取、基于标定CAN的读取、基于JTAG接口的读取等多种读取方式。

汽车黑匣子目前在汽车故障排查和事故调查中发挥中巨大的作用,主要有如下的应用:

Ø 交通事故重建。通过黑匣子获取汽车碰撞前、碰撞后的数据并结合计算机仿真技术进行事故现场的重现,有利于排除主观因素,在数值重建和碰撞形态重建两方面提高事故重建的精度。

Ø 交通事故调查与司法鉴定。非典型碰撞形态的交通事故车速鉴定、驾驶员操作行为鉴定一直是交通事故司法鉴定的难题,黑匣子数据帮助避免复杂的计算过程,同时大大降低计算误差。

Ø 车辆安全性改善。黑匣子记录了与车辆安全系统相关的大量数据,特别是与碰撞相关的速度、速度变化、气囊展开情况、乘员安全带使用情况、驾驶人应急操作行为等信息,有助于评估安全系统在实际事故中的效果,帮助车企及安全供应商针对实际情况对汽车安全性能进行迭代升级。

玄武软件著作权登记证书

玄武软件产品登记证书

点击下载产品手册