- 知从MCAL产品定制开发服务

- 知从VECTOR FBL产品工程服务

- 知从基于恩智浦S32K3系列芯片功能安全包可提供的服务

- 知从LIN一致性测试服务

- 知从科技基于英飞凌MOTIX™系列芯片 提供基础软件解决方案

- 知从基于恩智浦S32K3系列芯片功能安全包可提供的服务

- 知从E2E测试服务

- 从TRICORE平台到ARM CORTEX-R52/R52+的迁移指南

- 知从RTE测试服务

- 知从木牛恩智浦S32K1信息安全服务手册

- 知从嵌入式自动化测试服务

- 瑞萨RH850 G3MH/G3KH到ARM CORTEX-R52/R52+的迁移指南

- 知从ASPICE SWE04单元测试介绍

- 知从啸天信息安全算法工具(可直接下载试用)

- 知从功能安全工程服务

- 知从SafetyLibrary服务

- 知从VECTORMICROSAR产品工程服务

- 知从MCAL产品工程服务

- 知从ECU控制器开发功能服务

- 知从软件测试工程服务

- 知从HIL测试工程服务

- 知从TESTFACTORY工程服务

- 知从ADAS域控制器英飞凌MCU TC397

- 知从网关产品

- 便携式充电器

- 交流充电桩产品

1 概述

E2E(End-To-End)是AUTOSAR为功能安全ISO26262提出的一个安全模块,是一种针对安全相关数据,为防止通信链路中可能存在的故障(HW/SW), 在通信节点之间执行的 一种数据保护协议/机制。其适用于多种网络结构:CAN、CANFD、FlexRay、Ethernet等。

E2E的测试主要包含SWC间的通信测试,但从目前市场情况来看,随着AUTOSAR架构的复杂性增加,E2E测试的设计和实施变得更加复杂,测试用例的创建和管理也变得更具挑战性。尽管设计了多个测试用例,但可能仍无法覆盖所有边界情况和潜在错误,导致某些问题在实际使用中未被发觉。针对成百上千条的E2E报文,以及E2E报文所对应的DTC测试量巨大且消耗大量人力资源。

针对以上问题,上海知从科技有限公司提供完整的E2E测试服务,可有效提高客户E2E测试效率,降低E2E测试成本。

2 测试点

E2E测试主要针对于SWC之间的通信测试,根据不同的CRC校验制定不同的测试策略。包括但不限于:

Ø DataID的使用

Ø Counter的变化

Ø CRC的计算规则

Ø 相关DTC的测试

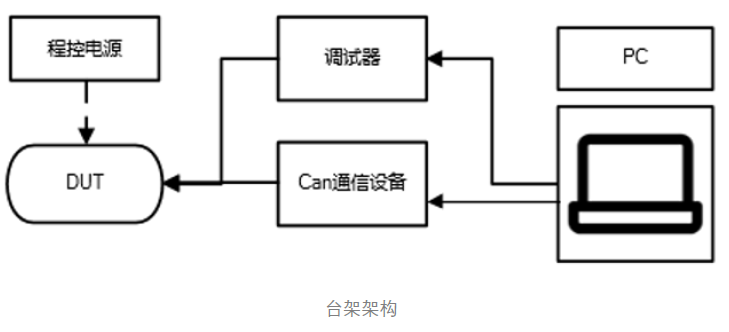

3 测试台架及通用环境

4 测试设备说明

4.1 硬件需求

知从科技具备完善的E2E测试设备,可有效的支撑E2E测试工作开展。

4.2 软件需求

4.2.1测试环境软件:

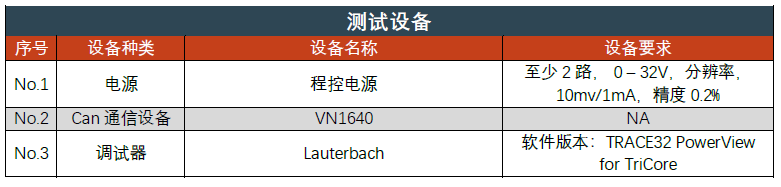

Vector CANoe 系列工具,版本Canoe12.0

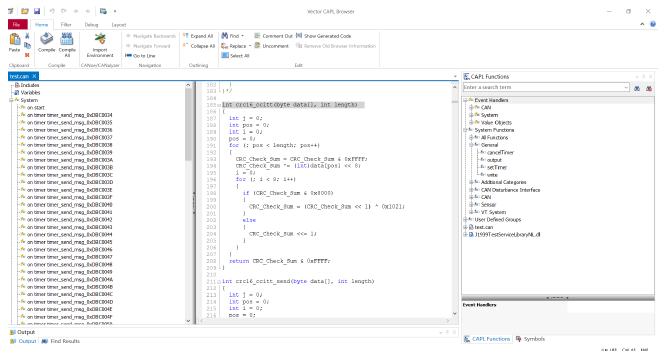

4.2.2TRACE32

5 E2E测试步骤示例

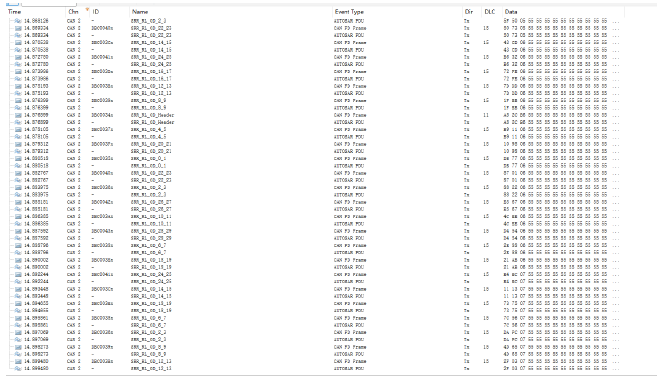

5.1 上位机模拟发送E2E报文

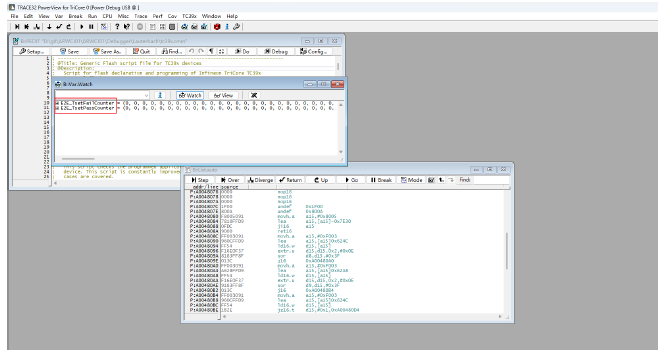

5.2 上位机模拟发送E2E报文通过调试器观测

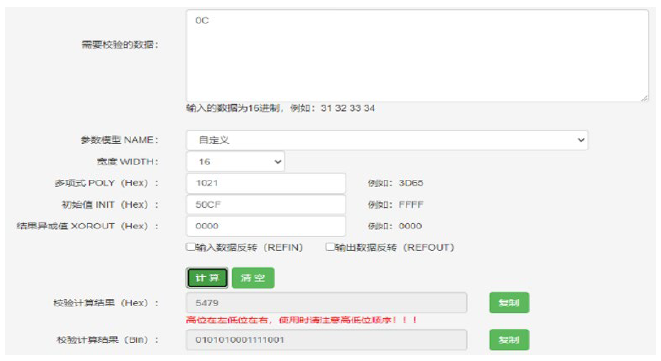

5.3 上位机接受报文,对比报文中的E2E数据,通过自研工具计算是否正确。

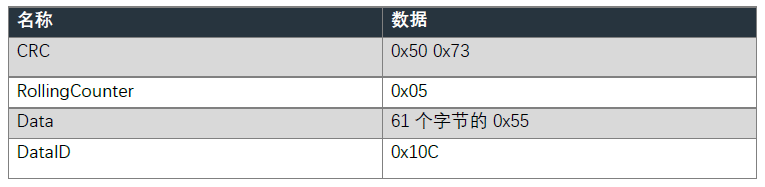

如ID:0xDBC0040,以E2E - Profile05为例子

第一步:计算数据的CRC值,初始值为0xFFFF

第二步:计算DataID中的的LowID的CRC值,初始值为第一步计算得到的值:0x50CF

第三步:计算DataID中的的HighID的CRC值,初始值为第一步计算得到的值:0x5479

最终得到CRC值:0x50 0x73

5.4 测试报告

根据AUTOSAR_CP_SWS_E2ETransformer规范和客户E2E的测试需求,并通过等价类,边界值等方法设计测试用例,完成测试报告,保证双向追溯性和一致性。

点击下载产品手册