工程服务

- 知从MCAL产品定制开发服务

- 知从VECTOR FBL产品工程服务

- 知从基于恩智浦S32K3系列芯片功能安全包可提供的服务

- 知从LIN一致性测试服务

- 知从科技基于英飞凌MOTIX™系列芯片 提供基础软件解决方案

- 知从基于恩智浦S32K3系列芯片功能安全包可提供的服务

- 知从E2E测试服务

- 从TRICORE平台到ARM CORTEX-R52/R52+的迁移指南

- 知从RTE测试服务

- 知从木牛恩智浦S32K1信息安全服务手册

- 知从嵌入式自动化测试服务

- 瑞萨RH850 G3MH/G3KH到ARM CORTEX-R52/R52+的迁移指南

- 知从ASPICE SWE04单元测试介绍

- 知从啸天信息安全算法工具(可直接下载试用)

- 知从功能安全工程服务

- 知从SafetyLibrary服务

- 知从VECTORMICROSAR产品工程服务

- 知从MCAL产品工程服务

- 知从ECU控制器开发功能服务

- 知从软件测试工程服务

- 知从HIL测试工程服务

- 知从TESTFACTORY工程服务

- 知从ADAS域控制器英飞凌MCU TC397

- 知从网关产品

- 便携式充电器

- 交流充电桩产品

知从LIN一致性测试服务

简介

LIN总线广泛应用于汽车行业,涵盖车窗控制、座椅控制、后视镜控制、天窗控制、灯光控制等多个应用领域。LIN总线具备低速、主从式通信和单线传输等特点,主节点承担着通信调度和网络管理的重要职责,从节点的正确响应也至关重要。因此,为确保LIN通信的可靠性和稳定性,在LIN主节点和从节点之间进行协议一致性测试显得尤为重要。

LIN总线的目的是低成本,但是在测试领域,LIN工具稀少且昂贵,原因是市场规模小,多数供应商无愿开发Lin测试工具,导致测试工具的选择极其有限,且价格昂贵。而且纵观全行业,大部分和LIN相关的工具,都是应用层面的工具,基本只能实现LIN报文的收发,对于物理层、网络管理等领域的测试无能为力。

针对以上描述的问题,知从科技可以提供一整套完整的Lin一致性测试方案,解决客户的后顾之忧。

详细介绍

1.测试规范

Lin主要的测试规范分为以下三类,知从科技针对这三类测试规范都有一套成熟的测试用例及方法。

[1] LIN Specification Package 2.2A;

[2] SAE J2602 – 1, 2;

[3] ISO 17987 – 2, 3, 4, 6, 7;

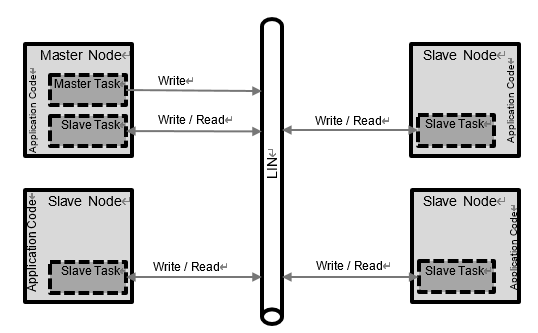

2.测试对象

配置LIN收发器的ECU

Ø 主节点Master Node;

Ø 从节点Slave Node;

LIN 总线系统结构:

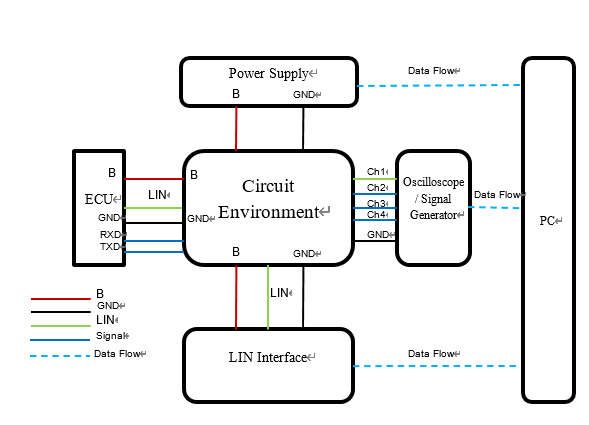

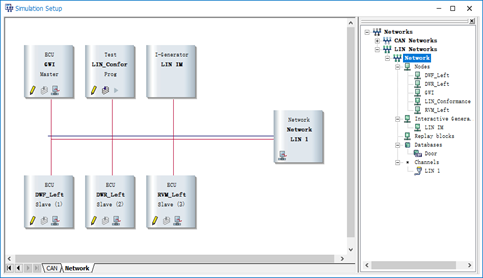

3.测试台架及环境

台架架构

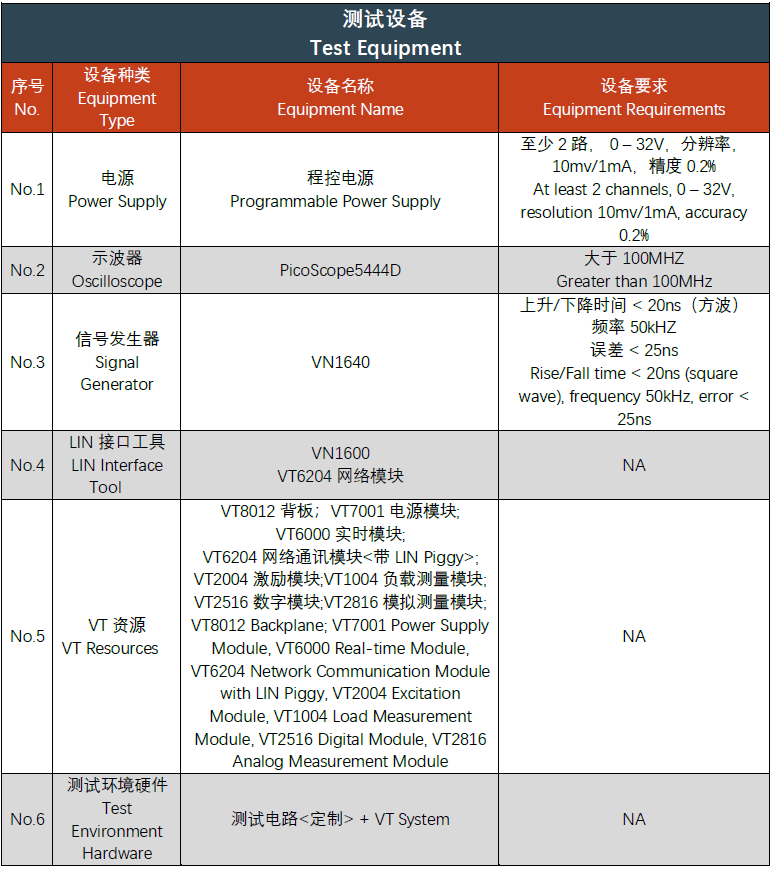

4.测试设备说明

4.1硬件需求

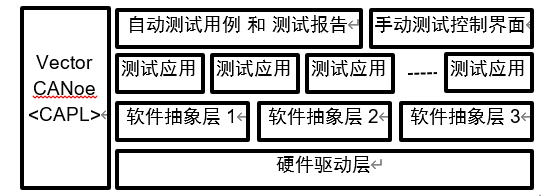

4.2软件需求

4.2.1测试环境软件:

Vector CANoe 系列工具

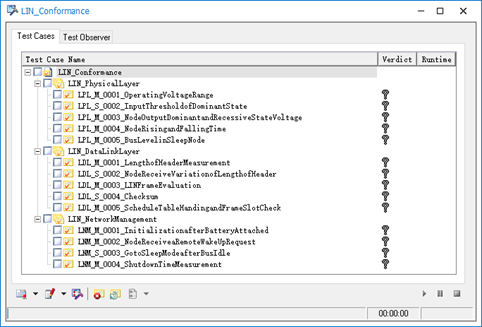

4.2.2测试用例控制

Test Module

4.2.3测试代码架构

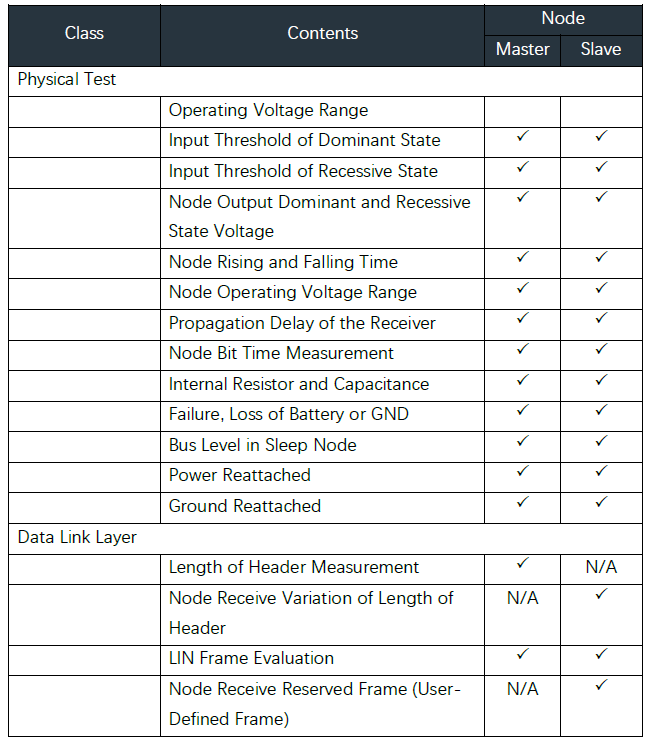

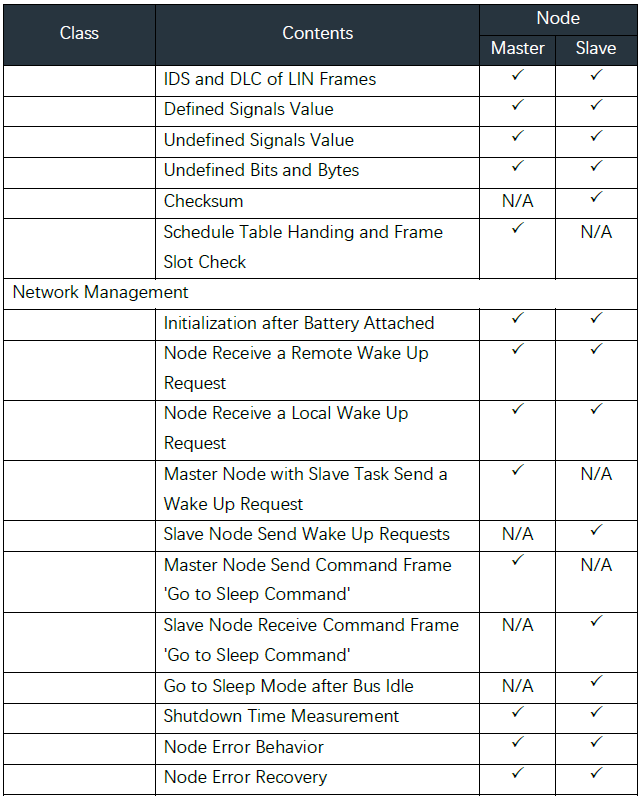

5.LIN一致性测试内容

6.测试需求输入

Ø LIN通讯设计规范

Ø LIN节点原理图 LIN

Ø 零部件接口定义文档

Ø 数据库文件LDF

Ø 休眠唤醒时序图

Ø 其他需求

相关证书

相关下载

产品手册

点击下载产品手册