- 知从MCAL产品定制开发服务

- 知从VECTOR FBL产品工程服务

- 知从基于恩智浦S32K3系列芯片功能安全包可提供的服务

- 知从LIN一致性测试服务

- 知从科技基于英飞凌MOTIX™系列芯片 提供基础软件解决方案

- 知从基于恩智浦S32K3系列芯片功能安全包可提供的服务

- 知从E2E测试服务

- 从TRICORE平台到ARM CORTEX-R52/R52+的迁移指南

- 知从RTE测试服务

- 知从木牛恩智浦S32K1信息安全服务手册

- 知从嵌入式自动化测试服务

- 瑞萨RH850 G3MH/G3KH到ARM CORTEX-R52/R52+的迁移指南

- 知从ASPICE SWE04单元测试介绍

- 知从啸天信息安全算法工具(可直接下载试用)

- 知从功能安全工程服务

- 知从SafetyLibrary服务

- 知从VECTORMICROSAR产品工程服务

- 知从MCAL产品工程服务

- 知从ECU控制器开发功能服务

- 知从软件测试工程服务

- 知从HIL测试工程服务

- 知从TESTFACTORY工程服务

- 知从ADAS域控制器英飞凌MCU TC397

- 知从网关产品

- 便携式充电器

- 交流充电桩产品

1 Test Factory介绍

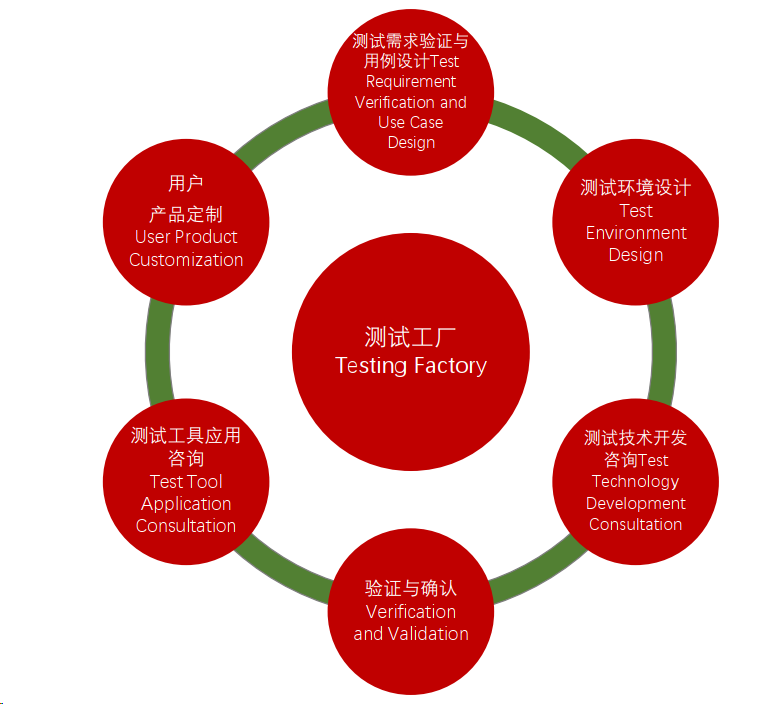

汽车行业发展进入高速发展期,尤其是智能驾驶研发,其中软件代码量急剧上升,对汽车功能和性能的要求不断升高,研发周期不断缩短,对测试任务提出了更高要求。为了最大可能重复利用可重复利用的资源,以及降低成本,测试工厂可以为客户提供系统需求验证,通讯诊断验证,功能验证,性能测试,功能安全,信息安全评估以及测试技术咨询,测试仿真环境设计和工具使用。

图 1‑1 测试工厂服务

2 TEST Factory 服务保证

2.1 测试需求验证与用例设计

收集客户产品需求及系统环境需求,软件需求,硬件需求,并进行详细分析验证,按需求工程理论,测试策略,测试技术,编辑和管理测试需求说明文档。

服务范围:

Ø 企业标准需求分析,如:总线设计标准,网络设计标准,诊断服务标准等,以企业标准为高优先级;

Ø 客户需求,系统设计需求验证,如:具体产品的系统需求,BCM,BMS,VCU等

Ø 软件功能分析,详细的软件逻辑功能模块;

Ø 功能安全需求分析,如:按功能安全ISO26262进行测试设计;

Ø 信息安全分析,依据ISO 21434,SAEJ3061-2016开展分析验证。

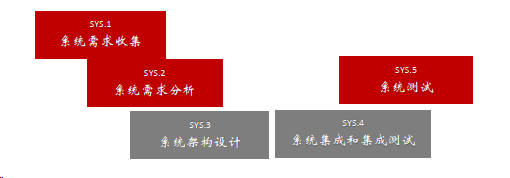

图 2‑1 系统工程流程

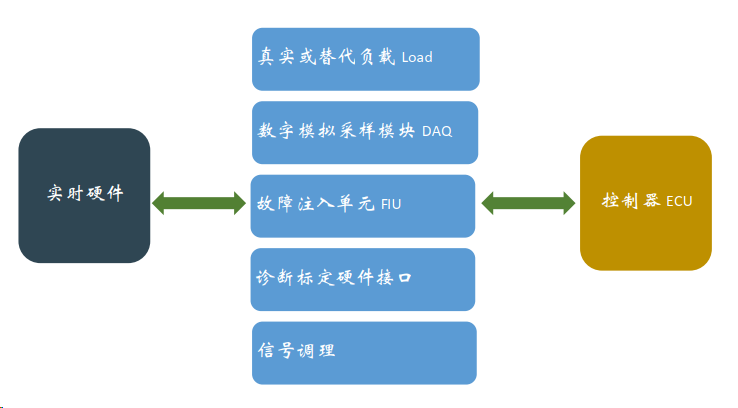

2.2 ECU测试

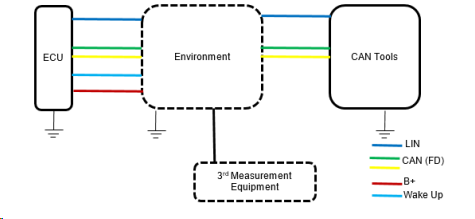

图 2‑2 ECU 测试环境示意图

Ø 标准测试

依据企业标准提供测试服务:

a) CAN(FD)总线一致性测试,涵盖了物理层,数据链路层,总线容错,采样点等;

b) LIN总线一致性测试, 涵盖了物理层,数据链路层,节点配置/网络管理;

c) 车载以太网测试,物理层测试,分发送端测试、接收端测试、线缆连接器合规性测试;

d) CAN网络管理测试,涵盖OSEK 网络管理,AutoSAR网络管理,主从节点网络管理;

e) 诊断服务测试,涵盖CAN诊断服务,LIN诊断服务;

f) Boot loader测试。

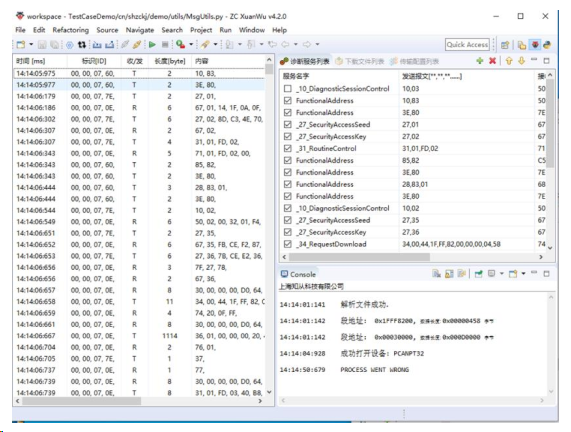

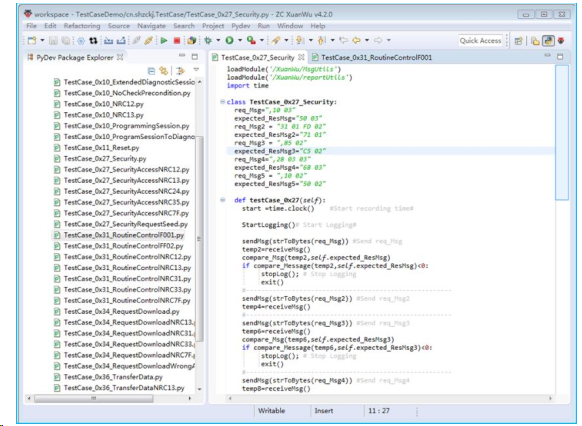

图 2‑3 玄武诊断服务

图 2‑4 玄武诊断服务测试用例

Ø 功能性测试

针对具体电子控制器功能测试,如:电池管理单元,车身控制单元,整车控制单元,车门控制单元,混合动力控制器等。

验证ECU的功能和技术要求的正确性,完整性。

a) ECU模型测试;

b) ECU系统测试;

c) ECU软件子功能测试;

d) ECU电源管理验证;

e) ECU功能安全需求测试;

f) ECU信息安全需求测试;

g) ECU验收测试<或发布测试>;

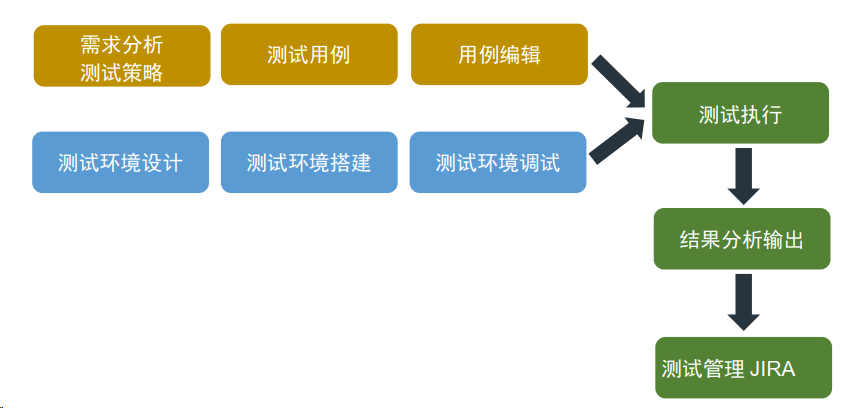

图 2‑5 测试开发基本流程

针对安全性机制,以及覆盖率还需进行更多验证,

Ø 故障注入验证,诊断应用测试,基于功能安全目标测试等;

Ø 经验验证;

Ø 与模型比较验证;

Ø 鲁棒性验证,压力测试,耐久测试,负载测试,可靠性测试;

2.3 整车测试

Ø 整车节点网络通讯验证, 可分AutoSAR 网络管理,OSEK网路管理,主从式网络管理;

Ø 整车功能仿真验证;

Ø 实车功能验证;

Ø 实车故障分析;

Ø 整车标定测量;

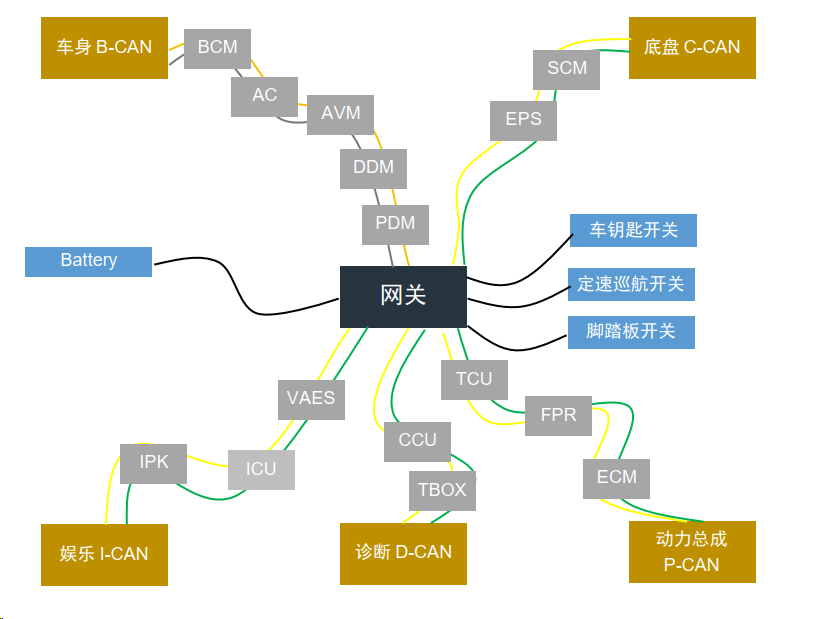

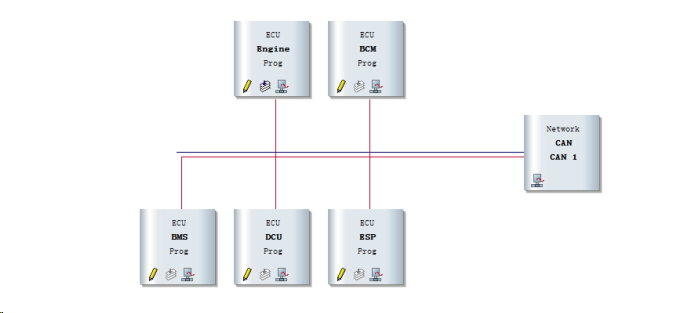

图 2‑6 整车网络拓扑示意图

2.4 测试环境设计

Ø HIL 测试系统方案设计

需求评估;

硬件环境搭建,实时仿真系统选择,

Ø VT System

Ø DSPACE

Ø NI

测试软件设计,可划分为:测试应用层,测试功能层,抽象层,驱动层。

图 2‑7 测试软件架构示意图

参考应用工具:Vector CANoe + vTESTstudio + VT System.

Ø 整车网络仿真环境设计

Design of vehicle network simulation environment

依据客户数据库Data Base文件的输入,进行网络通讯环境的仿真设计,如:

Ø 符合OSEK Nm通讯环境,基于OSEKNM01.dll;

Ø 符合AutoSAR Nm通讯环境,基于AsrNM33.dll或AsrNM30.dll。

注:建议定制仿真软件包,玄武工具包。

图 2‑8 网络仿真节点示意图

参考应用工具:Vector CANoe软件 + Vector 通讯硬件。

Ø 手动测试负载仿真环境设计

电源管理控制,总线(CAN, LIN,Ethernet)通讯环境,负载仿真,故障注入控制;

参考应用工具:非标定制 - 总线及IO仿真箱。

Ø HIL系统与待测ECU闭环调试

结合被测对象功能和系统环境,调试手动环境,并进行自动化测试用例开发。

2.5 测试技术开发及工具应用咨询

Ø 测试理论

涵盖测试开发基本过程,测试级别,测试类型,测试策略,测试技术,测试管理,测试工具支持等。

Ø 测试技术咨询

基本测试技术方法应用,等价类划分,边界值分析,决策表分析,状态转换测试,用例测试,组合测试,基于经验的测试技术,故障注入测试,以及基于检查表,基于质量特征验证等。

Ø 测试工具技术咨询及应用

Ø 总线工具,CANoe

Ø 诊断测试工具

Ø 测量标定

Ø HIL 系统

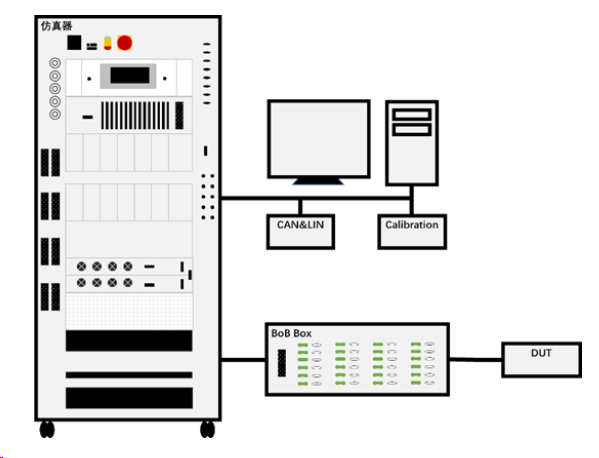

Ø HIL环境搭建技术咨询

以VT System环境搭建为例:

Ø 被测对象功能需求评估,负载资源评估;

Ø VT 资源板卡选型与确定;

Ø 系统平台化设计;

Ø HIL环境测试软件平台设计 ;

图 2‑9 硬件在环系统示意图

2.6 用户产品定制

Ø 桌面手动测试箱

Ø HIL自动化测试柜

Ø CAN(FD)一致性测试柜

Ø LIN一致性测试柜

图 2‑10 标准化HIL自动化测试系统

点击下载产品手册