- 知从木牛基础软件OBD

- 知从木牛基础软件英飞凌TC264

- 知从木牛OSEK网络管理恩智浦S32K344

- 知从木牛操作系统OS

- 知从木牛操作系统OS SC4

- TRICORE平台移植到ARM平台指导手册

- 知从木牛操作系统OS ARM CORTEX R52+

- 知从木牛基础软件英飞凌TC4X

- 知从木牛基础软件恩智浦S32K3

- 知从木牛基础软件英飞凌TLE989X

- 知从木牛AFE德州仪器BQ756506

- 知从木牛基础软件瑞萨RH850U2AX

- 知从木牛AUTOSAR软件平台英飞凌TC264

- 知从木牛基础软件杰发AC781X

- 知从木牛操作系统OS NG HYPERVISOR

- 知从木牛基础软件杰发AC7840

- 知从木牛基础软件瑞萨RH850F1KM

- 英飞凌TC3XX_Cache和Overlay功能详解

- 知从木牛基础软件芯旺微KF32A产品手册

- 知从木牛基础软件恩智浦S32K344产品

- 知从木牛基础软件紫光同芯THA6206

- 知从木牛基础软件平台

- 知从木牛AUTOSAR软件平台恩智浦S32K

- 知从木牛AUTOSAR软件平台恩智浦MPC5744P

- 知从木牛AUTOSAR软件平台英飞凌TC275

- 知从木牛SOC产品

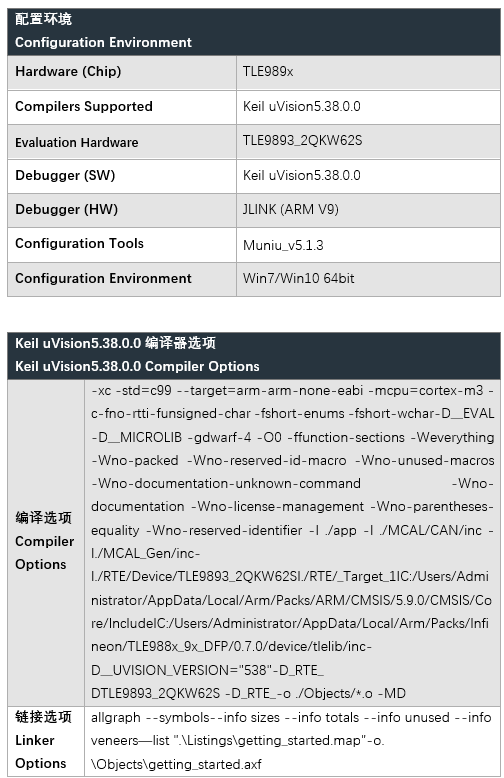

AUTOSAR组织成立于2003年,主要由欧洲汽车制造商、部件供应商及其他电子、半导体和软件系统公司联合建立。致力于为汽车工业开发一个开放的、标准化的软件架构,希望大家“在标准上合作,在应用上竞争”,提高控制器产品开发质量和速度。2006年底发布了2.1版规范,2008年发布3.1版本开始产品化,并逐步增加了功能安全、以太网等内容。目前广泛使用4.2.1、4.2.2以及4.3.1版本。

汽车在电动化、网联化、智能化的大趋势下,电子电器部件日益增多,电气结构越加复杂,整车开发周期不断缩短。平台化、智能化的基础软件起到至关重要。

知从科技掌握AUTOSAR平台软件的开发和应用核心技术,提供本地现场支持,质量好,速度快,成本低。

产品特点

Ø 符合AUTOSAR 4.3.1版本

Ø ARTOP架构上位机配置工具,最高适配AUTOSAR 4.4.0版本

Ø 操作系统

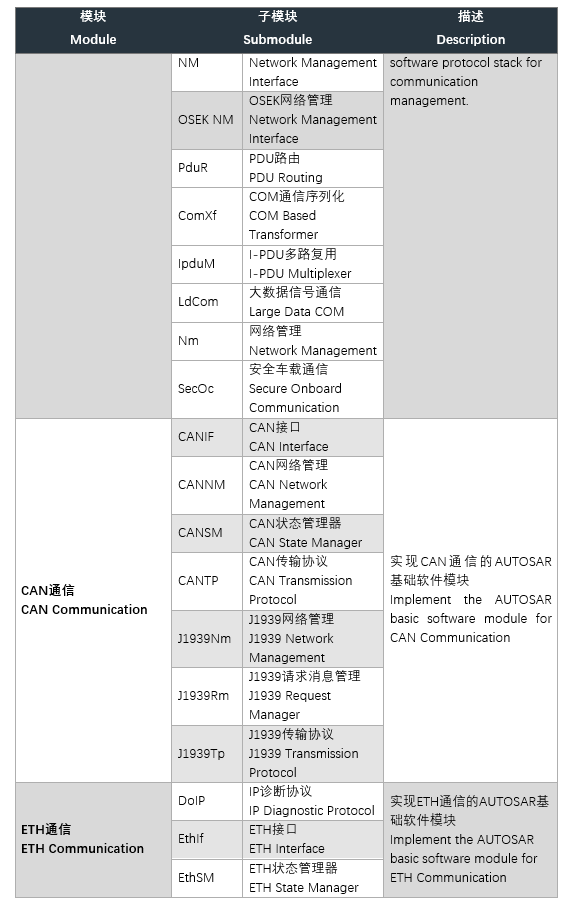

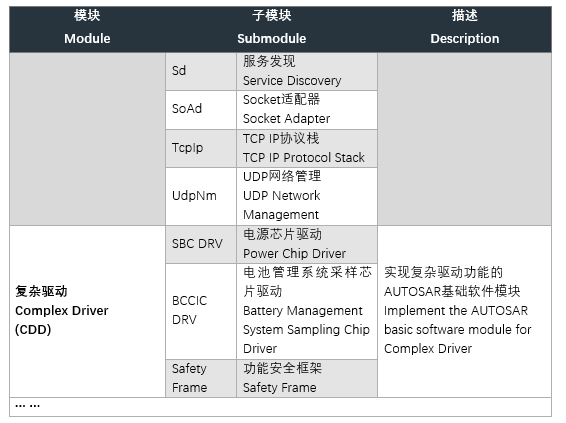

Ø 通讯协议栈

Ø 诊断协议栈

Ø 网络管理

Ø 标定协议栈

Ø 存储协议栈

Ø 复杂驱动定制开发

Ø 工程服务

CANFD MCAL功能介绍

CANFD MCAL满足AUTOSAR 4.3.1版本,可支持最大64字节的CAN FD报文,在CAN模式下可达到1 Mbit/s的速率,在CANFD模式下可达到2 Mbit/s。消息对象可以配置为接收11位标识符的标准帧或29位标识符的扩展帧,或者同时接收标准帧和扩展帧。也可以被分组为不同的优先级类,用于发送和接收。

l 发送功能

在发送 CANFD数据时调用Can_Write()函数请求传输CANFD消息,当CANFD的数据传输完成后,会触发发送中断,通知上层模块进行后续操作。

l 接收功能

在接收CANFD总线上传输的数据帧时触发接收中断处理函数Can_IsrReceiveHandler (),对接收到的CANFD数据帧进行检查,将提取到的数据解析并转换为控制器或处理器可读取的格式,存储在Can_RxMessageData Buffer中。

l 中断处理

CANFD中断可以用于处理以下事件:

接收中断:当接收到CANFD总线上的新消息时,控制器会产生接收中断,进入接收中断处理函数Can_Isr ReceiveHandler(),处理接收事件和唤醒事件,并调用CanIf_RxIndication()通知函数。错误中断:当CAN FD总线发生错误时,例如有错误帧或者总线错误等情况,控制器会产生错误中断,以便处理器及时处理。

发送中断:当CAN FD总线上的数据传输完成时,控制器会产生传输中断,进入发送中断处理函数Can_IsrTransmitHandler(),处理帧传输成功事件,并调用CanIf_TxConfirmation()通知函数,以便处理器进行后续操作。

l FIFO功能

FIFO用于避免传入消息的丢失(接收FIFO) 并尽量减少传出消息 (发送FIFO) 的设置时间。FIFO结构也可用于自动接收或发送一系列CAN消息,并在整个CAN帧完成后产生一个单一的报文中断。

l FIFO功能

FIFO用于避免传入消息的丢失(接收FIFO) 并尽量减少传出消息 (发送FIFO) 的设置时间。FIFO结构也可用于自动接收或发送一系列CAN消息,并在整个CAN帧完成后产生一个单一的报文中断。

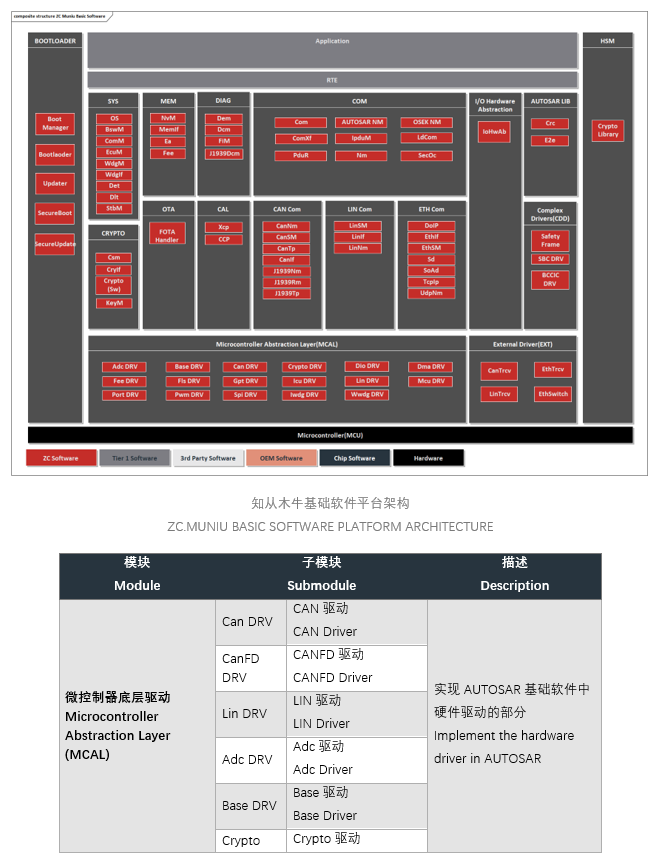

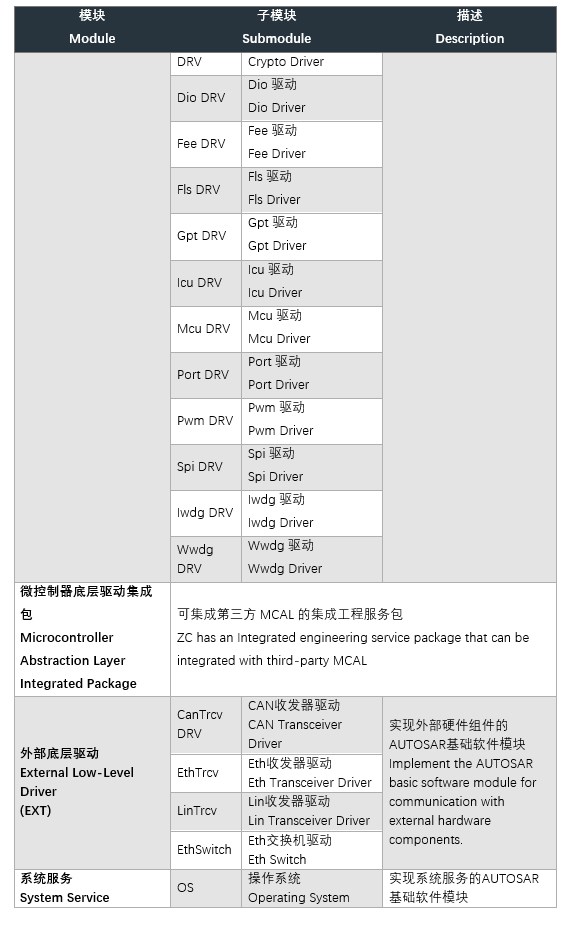

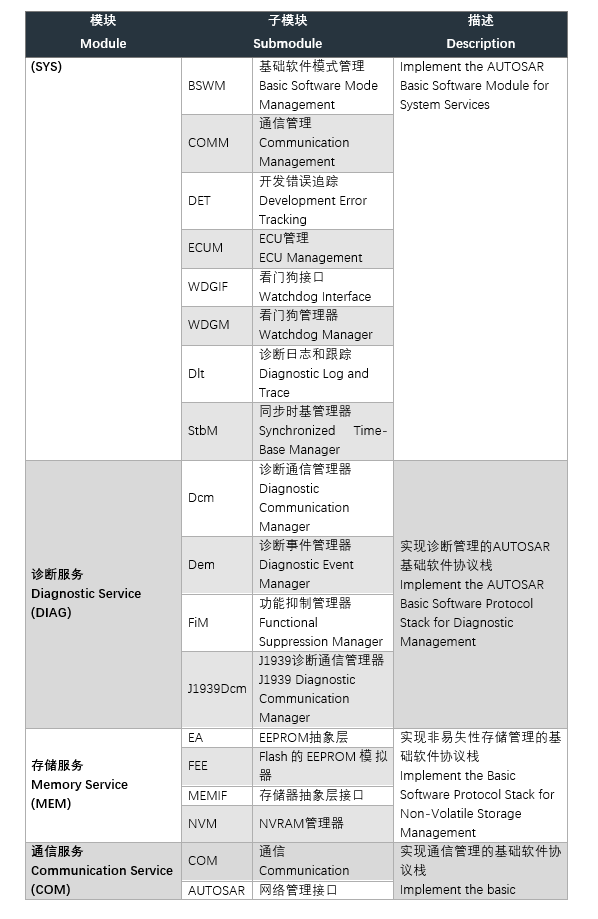

知从.木牛( ZC.MuNiu )为汽车电子控制器产品开发,提供完整的基础软件平台解决方案。该产品参考AUTOSAR、OSEK等国际规范,有基于AUTOSAR ATOP架构的上位机配置工具,支持上汽、一汽、吉利、广汽、长安、长城等整车厂通讯、诊断、网络管理、启动刷新规范。知从木牛英飞凌TC264基础软件平台,主要包括:操作系统、通讯协议栈(CAN\LIN)、诊断协议栈(UDS\J1939)、网络管理(OSEK\AUTOSAR)、标定协栈(XCP\CCP)、存储协议栈、复杂驱动模块等,配套知从的Bootloader刷新程序和上位机工具,可以根据不同的客户项目要求进行配置和再开发。知从科技提供基础软件产品的同时,也提供控制器基础软件功能实现的开发服务。

英飞凌TLE989x的安全等级为ASIL B,拥有32位Arm Cortex-M3内核,最高可达60MHz,支持Arm Cortex-M3内核操作系统。知从科技能基于英飞凌TLE989x提供符合ASPICE Level2流程和功能安全ASIL B要求的基础软件产品。

木牛基础软件平台可应用于使用英飞凌TLE989x系列芯片的汽车电子控制器产品开发。

例如:

Ø 汽车电子水泵控制器

Ø 发动机冷却风扇控制器

Ø 滑动车门控制器

Ø 汽车门锁控制器

Ø 汽车天窗控制器

Ø 空调控制器

木牛软件著作权登记证书

点击下载产品手册